Whether you're a gamer chasing milliseconds or a professional navigating spreadsheets, the humble mouse pad plays a vital role in your daily computing experience. What seems like a simple accessory is actually the result of a fascinating, multi-stage manufacturing process. Let’s take a journey through a modern mouse pad factory to explore how these everyday essentials are made — from fabric to finish.

1. Design & Material Selection

Everything begins at the design table. Mouse pads today come in various sizes, shapes, and textures, catering to different user preferences. Designers consider both functionality and aesthetics. For gaming mouse pads, high-DPI compatibility and smooth glide are priorities, while office pads may focus on wrist support or branding.

Materials are carefully selected for durability and performance. The most common mouse pad consists of three layers:

- A textile surface (usually polyester or microfiber) for optimal tracking.

- A rubber or foam core for cushioning and flexibility.

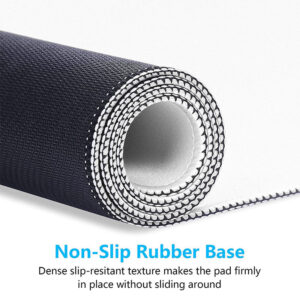

- A non-slip base, often made of natural rubber or silicone, to keep the pad firmly in place.

2. Cutting & Layering

Once materials are chosen, they’re cut into sheets. Using precision cutting machines, the factory slices the raw fabric and rubber into the desired dimensions. For custom or ergonomic designs, laser cutters are employed to achieve intricate shapes without fraying the edges.

The layers are then laminated together. An industrial press bonds the textile surface to the rubber base using heat and durable adhesives. This ensures the mouse pad retains its shape and doesn’t peel over time.

3. Printing & Branding

Modern mouse pads double as marketing tools and artistic canvases. Sublimation printing is the most popular technique used to transfer vibrant, full-color images onto the textile surface. Designs are first printed on special transfer paper, then heat-pressed onto the pad, allowing the ink to fuse with the fibers.

This method ensures that the print won’t fade or rub off, even after prolonged use. Many factories also offer custom printing for promotional items, esports teams, and online creators.

4. Edge Stitching & Finishing

To enhance durability, many high-end mouse pads feature stitched edges. Automated machines sew tight, even stitching around the perimeter to prevent fraying. This step requires precision — uneven stitching can affect both appearance and user comfort.

After stitching, each pad undergoes a quality control check. Inspectors look for surface defects, color consistency, and structural integrity. Pads that fail to meet standards are recycled or reworked.

5. Packaging & Shipping

Once approved, the mouse pads are cleaned, flattened, and packaged — often rolled or laid flat in eco-friendly boxes. Bulk orders are palletized for shipping, while individual units are shrink-wrapped or boxed for retail sale.

Final Thoughts

From the selection of high-performance materials to the final stitch, the creation of a mouse pad is a blend of technology, craftsmanship, and attention to detail. Behind every smooth glide and precise click lies a journey of innovation that transforms raw fabric into a finished product ready for your desk.

So next time you rest your wrist on that soft surface, remember — it’s more than just a pad. It’s a product of modern manufacturing mastery.