Have you ever paused to consider the humble mouse pad? It’s one of the most overlooked yet essential tools in your daily digital life. Whether you’re gaming, designing, or just surfing the web, your mouse pad plays a crucial role in your comfort and productivity. But where did it come from—and how did it end up under your hand? Let’s take a journey through the life of a mouse pad, from factory floor to your desktop.

Raw Materials and Design

The story of a mouse pad begins with raw materials. Most standard mouse pads are made from a combination of rubber, foam, fabric, and sometimes plastic or even metal. Natural or synthetic rubber forms the base, giving the pad its flexibility and grip. A layer of fabric—usually polyester—is bonded to the top to provide a smooth surface for accurate mouse tracking.

Before production begins, designers determine the shape, size, thickness, and intended use of the pad. Gaming mouse pads, for instance, tend to be larger and optimized for speed or control, while office pads are more compact and utilitarian.

Manufacturing Process

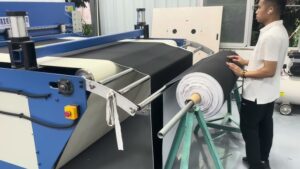

Once the design is finalized, the manufacturing process begins. Large sheets of rubber are cut into the desired shape and size using die-cutting machines. The top fabric layer is then laminated onto the rubber base using heat and adhesive. In some cases, printed designs or company logos are added through sublimation printing, which involves heat-pressing ink into the fabric for a long-lasting finish.

After the printing process, the edges of the mouse pad may be stitched for extra durability. This step helps prevent fraying and gives the pad a professional finish. The final product is then quality-checked for defects like uneven surfaces or misprints.

Packaging and Distribution

Once the mouse pads pass quality control, they’re packaged for shipment. Some are rolled and boxed individually, while others are stacked in bulk for wholesale distribution. From the factory, they’re sent to warehouses, retail stores, or directly to consumers via e-commerce platforms.

In some cases, custom mouse pads are made to order, especially for corporate branding or personalized gifts. These are often produced in smaller batches and shipped directly to the customer.

Life on the Desktop

After its journey from the factory, the mouse pad finally arrives at its destination—your desk. Here, it serves its purpose quietly but effectively. It provides a stable surface for your mouse, improves cursor accuracy, and protects your desk from wear and tear. Ergonomic mouse pads with wrist rests even help reduce strain during long hours of computer use.

Over time, your mouse pad might show signs of wear—fading designs, frayed edges, or loss of grip. Depending on its quality, a good mouse pad can last years before needing replacement.

Conclusion

Though it may seem simple, the life of a mouse pad is a story of thoughtful design, precision manufacturing, and everyday utility. The next time you glide your mouse across its surface, take a moment to appreciate the little rectangle of material that quietly supports your digital world.